Industrial construction continues to evolve as project planners seek materials that balance durability, indoor comfort, and efficient installation. With Polyphen Sandwich Panel gaining attention across clean environments and modular structures, yd-purification introduces practical building concepts shaped around performance and long-term usability. Could choosing the right panel system redefine how your facility functions every day?

Across laboratories, healthcare spaces, food processing areas, and manufacturing zones, wall systems are no longer selected only for appearance. Decision makers now consider insulation behavior, surface stability, and adaptability to controlled environments. Integrated panel structures help create consistent interiors where temperature management and hygiene standards work together naturally.

One growing discussion centers on streamlined construction workflows. Prefabricated panels support faster assembly while maintaining structural consistency, helping teams reduce on-site complexity. This approach supports organized project timelines and limits disruption, which matters greatly in renovation or expansion scenarios where operations often continue nearby.

Another important topic involves environmental awareness. Modern facilities increasingly prioritize materials that support long service life and reduced maintenance cycles. Durable panel systems help minimize replacement frequency while maintaining surface integrity, contributing to responsible building practices aligned with contemporary sustainability goals.

Interior performance also plays a significant role. Smooth finishes allow easier cleaning, while solid core structures support sound control and thermal balance. These qualities create comfortable workspaces that promote concentration and operational stability, especially in sensitive production areas where environmental consistency matters.

Design flexibility has become equally valuable. Today's panel solutions support modular layouts, allowing spaces to adapt as business needs shift. Whether expanding production lines or reorganizing interior zones, adaptable systems provide freedom without requiring full reconstruction, offering practical advantages for growing facilities.

Fire safety and structural reliability remain essential considerations. Advanced panel designs address these priorities through thoughtful composition, helping meet project requirements across industrial and commercial applications. Builders appreciate materials that combine protective properties with streamlined installation methods.

Maintenance efficiency is another factor driving material selection. Panels designed for easy surface care help facility managers maintain clean interiors without complex procedures. This simplifies daily operations while supporting hygiene expectations in controlled environments such as clean rooms and technical workshops.

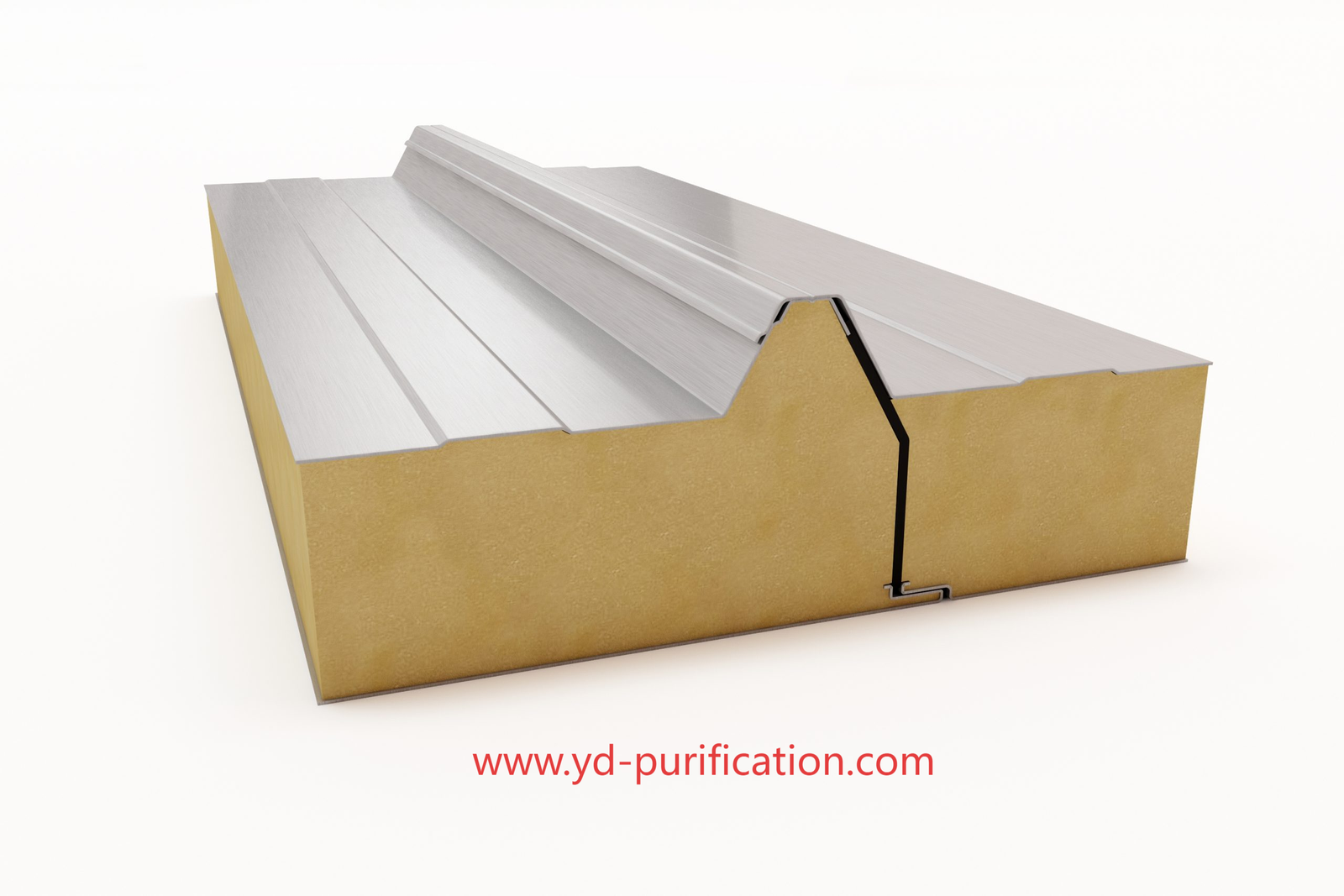

Behind each engineered panel lies careful material coordination and manufacturing precision. From surface layers to internal cores, every element contributes to overall performance. Yd-purification focuses on delivering solutions that integrate smoothly into modern construction projects, supporting consistent results from planning through completion.

Global building trends continue moving toward integrated systems that reduce fragmentation across design, supply, and installation. Panel-based construction aligns with this direction by offering unified solutions that connect architecture with functionality, supporting efficient collaboration between engineers, contractors, and facility operators.

For developers and project teams seeking dependable wall systems that support evolving industrial standards, yd-purification offers practical pathways forward. Learn how advanced panel applications fit into modern construction by visiting https://www.yd-purification.com/news/industry-news/what-s-the-advantages-of-polyphen-sandwich-panel.html and consider whether your next project is ready for a smarter structural approach.